Tracking Assets with RFID Technology

All businesses that rely heavily on the heavy movement of assets should use an assets management system that allows a good assets tracking system. Whether that be stock, items, equipment, vehicles, or even personnel A good assets management system should provide this functionality. Without this capability businesses not only risk being left behind by more serious competitors but they’ll also incur expenses that limit the profitably.

The functionality of the asses tracking tool is built around the overall goals of reducing costs and improving efficiency. This results in a variety of benefits that asset-intensive businesses can achieve.

The most important use of a tracking solution is to provide reliable monitoring of physical assets. This enables users, to keep close track of items as they move within their workplace and between various sites with greater visibility, accuracy, and efficiency.

Asset tracking tools can be used in a variety of ways for different processes. For instance, small businesses and retailers will use tracking tools for stock control while some large companies and manufacturers will utilize a tracking system to manage their supply chain. This will reduce their total cost of doing business.

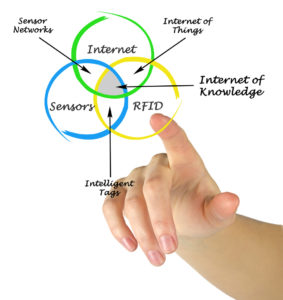

Traditionally companies have been using manual system of filling out data in spreadsheets and then tracking the items using barcodes and other manual systems. However, these old methods require a significant amount of manual labor. One way to quickly improve asset management is by utilizing radio frequency identification (RFID) technology to automatically track those assets.

RFID Technology

RFID asset tracking is a popular choice for businesses with a wide range of assets. It enables users to accurately track data in real-time and collect data from more

than one tag at once, as opposed to having to be in the line of sight that makes it a time-efficient and reliable tagging technology.

In RFID technology digital data encoded in RFID tags or smart labels that are captured by a reader transmitted by radio signals. This data is then stored in a database. RFID tag data can be read even if it is outside the line-of-sight.

RFID can provide accurate, real-time tracking data for fixed and mobile assets. Basically the RFID system has an RFID tag or smart label and an RFID reader. The RFID tags contain electronics on a chip coupled with an antenna which transmits data to the RFID reader. The reader translates the signal into readable data. Information collected from the tags is then transferred through a communications interface to a host computer system, where the data can be stored in a database and analyzed at a later time.

Types of RFID Tags

RFID can be active or passive. Active RFID tags come equipped with an onboard power supply and electronics. It actively transmits the data it collects to readers. Because it is always online and active, it can feed the readers with real-time data as it is received. Active RFID has a longer range than its passive counterpart. Some tags can read up to 300+ ft, which makes them ideal for larger job sites. In addition to tracking your tools, it can also help in tool maintenance by tracking how often it is serviced and whether it needs to be replaced. Passive RFID has a much shorter range and does not have any active electronics. However, they can be read by scanners and update the data automatically.

Advantages of using RFID Tags

The ability to automate your tracking and monitoring processes aims to put an end to the highly error-prone methods of pen-and-paper and excel spreadsheets. Among other benefits such as:

- Tracks multiple assets at any one time

- Eliminates human intervention

- Collects data in real-time

- Improves asset visibility

- Locates lost or misplaced assets

- Maximizes accuracy of inventory

- Monitor items checking in and out

- Reduces Loss and Theft

- Saves Time

A laptop with a RFID reader or even a smart phone the staff can easily scan one or more asset tags without having to physically see the tags. Previously with manual barcode scanners the staff would need to manually point a barcode scanner directly at the tag to get an accurate data. In some applications, that would require to go under stacks, racks and even climb up ladders to get to reach an item and scan it. With RFID, the reader can be quite a distance away and still get the correct information scanned in. A single staff member could easily scan hundreds of items in a very short time. RFID tags can be integrated with sensors and GPS technology to provide asset condition data, in addition to location information.

Asset security can be improved by generating real-time alerts and alarms if assets are moved into unauthorized locations or taken out of a building. You can also monitor items loaned out or checked out for repairs or calibration. This increases productivity as the assets can be located very quickly and accurately. Automated tracking with RFID can provide a complete overview of your entire assets set quickly and efficiently with almost no manual intervention. .

Managing and locating important assets is a key challenge for almost any business. Time spent searching for critical equipment can lead to expensive delays or downtime. Therefore consider using RFID tracks for tracking your assets.

Asset tracking using RFID can help you locate your assets easily with minimum loss at an acceptable cost. Anytime Assets provides the tracking functionality with RFID technology at a reasonable cost and provides you quick information on whatever assets you own, where they are, and who has them, all in real-time. Please contact Anytime Assets for complete details.